Various Applications

We provide a wide variety of displays for different applications. Use the filter below to narrow your search.

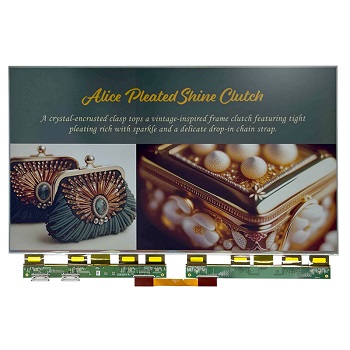

Retail, Signage, IoT

31.5" E Ink Spectra 6, Color ePaper Display

E Ink Spectra 6: Vivid Full Colors

Retail, Signage, IoT

25.3" E Ink Spectra 6, Color ePaper Display

E Ink Spectra 6: Vivid Full Colors

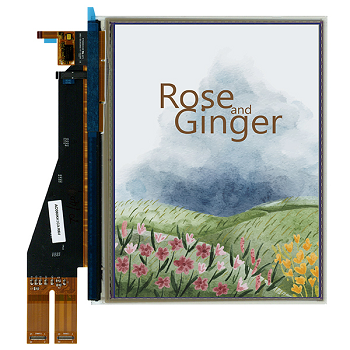

eReader, eNote

7.8" E Ink Kaleido 3 Color ePaper Display

4096 tender colors, with touch and front light, Anti-Glare film surface

eReader, eNote

7.8" E Ink Kaleido 3 Color ePaper Display

4096 tender colors, with glass touch and front light, PET surface and no Haze.

eReader, eNote

8" E Ink Gallery 3 Color ePaper Display

E Ink Gallery 3: Full Colors

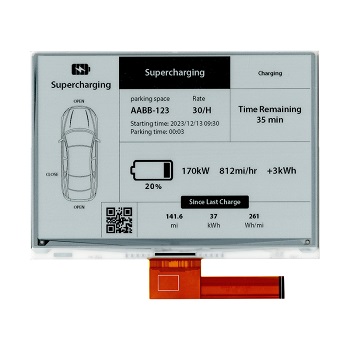

Tag, IoT, eBadge

4.3" E Ink Carta 1200, Monochrome ePaper Display

E Ink Carta 1200

eBadge, Tag, IoT

3.7" E Ink Carta 1200, Monochrome ePaper Display

E Ink Carta 1200

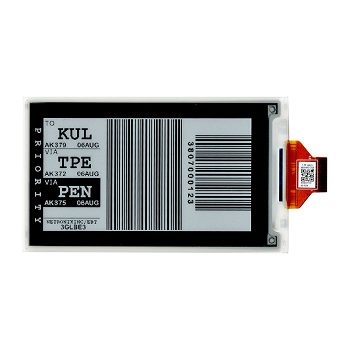

Logistic Label, IoT

7" E Ink Carta 1300 Monochrome ePaper Display

E Ink Carta 1300

Outdoor Signage, IoT

25.3" E Ink Kaleido 3 Outdoor Color ePaper Display

4096 tender colors, Wide temperature operating range from -15 to 65℃

License Plate, Outdoor Signage

11.3" E Ink Kaleido 3 outdoor Color ePaper Display

4096 tender colors, Wide temperature -15 to 65°C.

IoT, eBadge

2.8" E Ink Kaleido Color ePaper Display

4096 tender colors, text applicable.

IoT, eBadge

2.8" E Ink Kaleido Color ePaper Display

4096 tender colors